The following video of the sound test visualises the procedure and the test result.

It is intended as a support for use in the daily practice of technical vehicle inspection.

The following video of the sound test visualises the procedure and the test result.

It is intended as a support for use in the daily practice of technical vehicle inspection.

The following points should be observed when performing the sound test:

When performing the sound test, the brake must be released and the brake pads must not be in contact with the wheel rim.

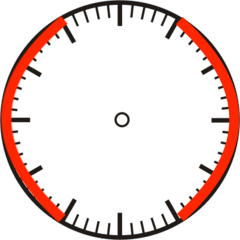

A hammer (with a steel hammer head, handle length not specified) is used to strike the front surface of the wheel rim or the wheel tread between 7 and 11 o'clock or 1 and 5 o'clock (relative to the full wheel circumference). For ergonomic reasons, a long handle is recommended.

The hammering must be carried out in such a way that no damage is caused to the wheelset.

An undamaged wheel without a cracked wheel rim sounds bright during a sound test.

A wheel with a cracked wheel rim will produce a dull sound.

If a wheel sounds dull, it is necessary to carefully inspect the entire wheel (especially the tread and wheel rim) for cracks.

Damaged wheelsets must be removed and replaced.